Welcome to Online Laboratory School

The following 3D virtual tours can be accessed using a mobile device and a computer. You can experience the interactive, immersive virtual walk-through in the Undergraduate Laboratory in the Wallberg Building via virtual reality headsets. Some sites and interactive functions such as self-study quizzes, virtual operation games, and discussion boards are only accessible to students during the academic term in Fall and Winter. All material on this website is copyrighted, and permission is required for copying or distributing any content.

Contact Prof. Ariel Chan at ariel.chan@utoronto.ca for more information and how you can be involved in many exciting projects.

Students Contributed to this Online Laboratory School Development:

- Jim Yao, Chemical Engineering and Applied Chemistry

- Namya Syal, Chemical Engineering and Applied Chemistry

- Athbi Alfadhli, Chemical Engineering and Applied Chemistry

- Jackie Liu, Computer Science

- Danny Wang, Industrial Engineering

- Semin Jo, Chemical Engineering and Applied Chemistry

Virtual Laboratory Tour: Wallberg Building WB25 and WB125 in 2020

Virtual Laboratory Tour: Wallberg Building WB202 and WB203 in 2020

Virtual Laboratory Tour: Wallberg Building WB25 and WB125 in 2019

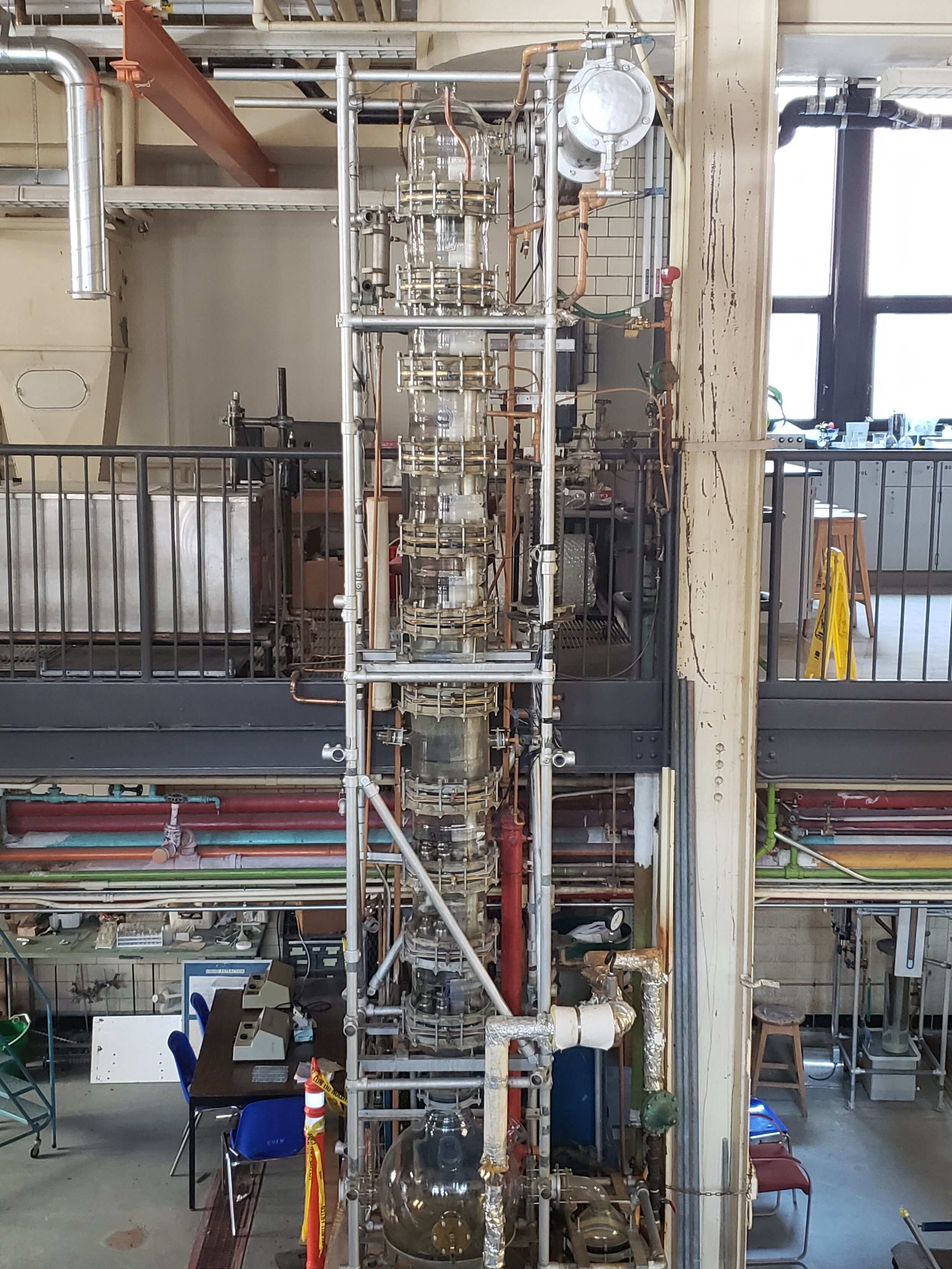

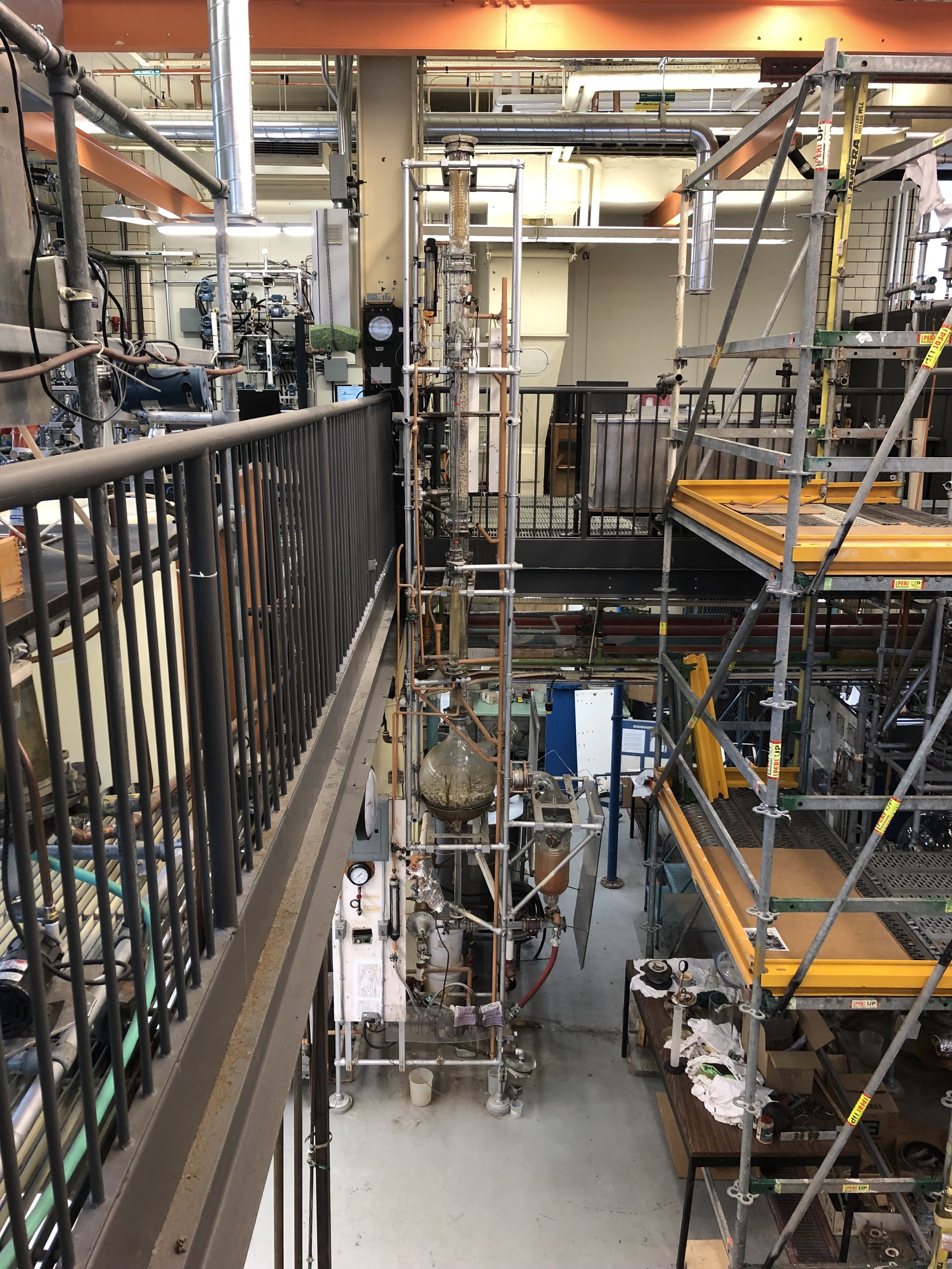

Collection of Pilot-Scale Chemical Process Units

Click on the images for more information, including P&ID, standard operation procedures, and engineering principles and concepts associated with operations.

Leaching is one of many solid-fluid separation processes that are carried out in the chemical, mineral and related industries. You will have the opportunity to explore the effects of operation methods and the nature of the solid to be leached on the leaching rate.

These processes can be quite complicated to design, where even a simple change in environment can greatly affect the results you were expecting. In this section, we will be discussing the theoretical concepts behind this process to get a better understanding of an approach to analyse the system.

Distillation is one of the earliest unit operations in human history. By the differences in boiling points and condensation points, you can separate different substances. In this lab, you will have the opportunity to explore the effects of changing various process parameters can have on the production rate and purity of the distillate product.

We will limit the scope of our discussion to simpler methods to analyze these systems. Looking at the Mccable-Thiele method, we will be able to examine complex systems simply using this method, which will allow us to gain a basic understanding of a distillation system.

Plate columns are one of the first separation processes every chemical engineer will study. These columns are widely used in industry for their ability to yield high quantities of product without the need of frequent shutdowns. However, in a lot of different processes, using plate distillation may not be suitable – it could be due to economics, yield or even practical applications (column too big).

Another form of distillation is using a packing material. The material is packed into the column, either in a random or structure manner, to provide a high contact area between the packing and the liquid/gas phase. We will investigate how to design a packed column, look at its advantages and disadvantages and compare them to a plated column.

Heat exchangers are very common in an engineering environment; they are vastly applicable and they come in different shapes and sizes. In this laboratory, you will learn about the operation and design of three types of heat exchangers: shell&tube, hairpin and plate. You have the opportunity to watch them operate and observe how the properties of the fluids inside.

We will be investigating the theory behind heat transfer and transport phenomenon, which is applicable to many industries in chemical engineering. Understanding these concepts will make up the fundamentals of your chemical engineering education.

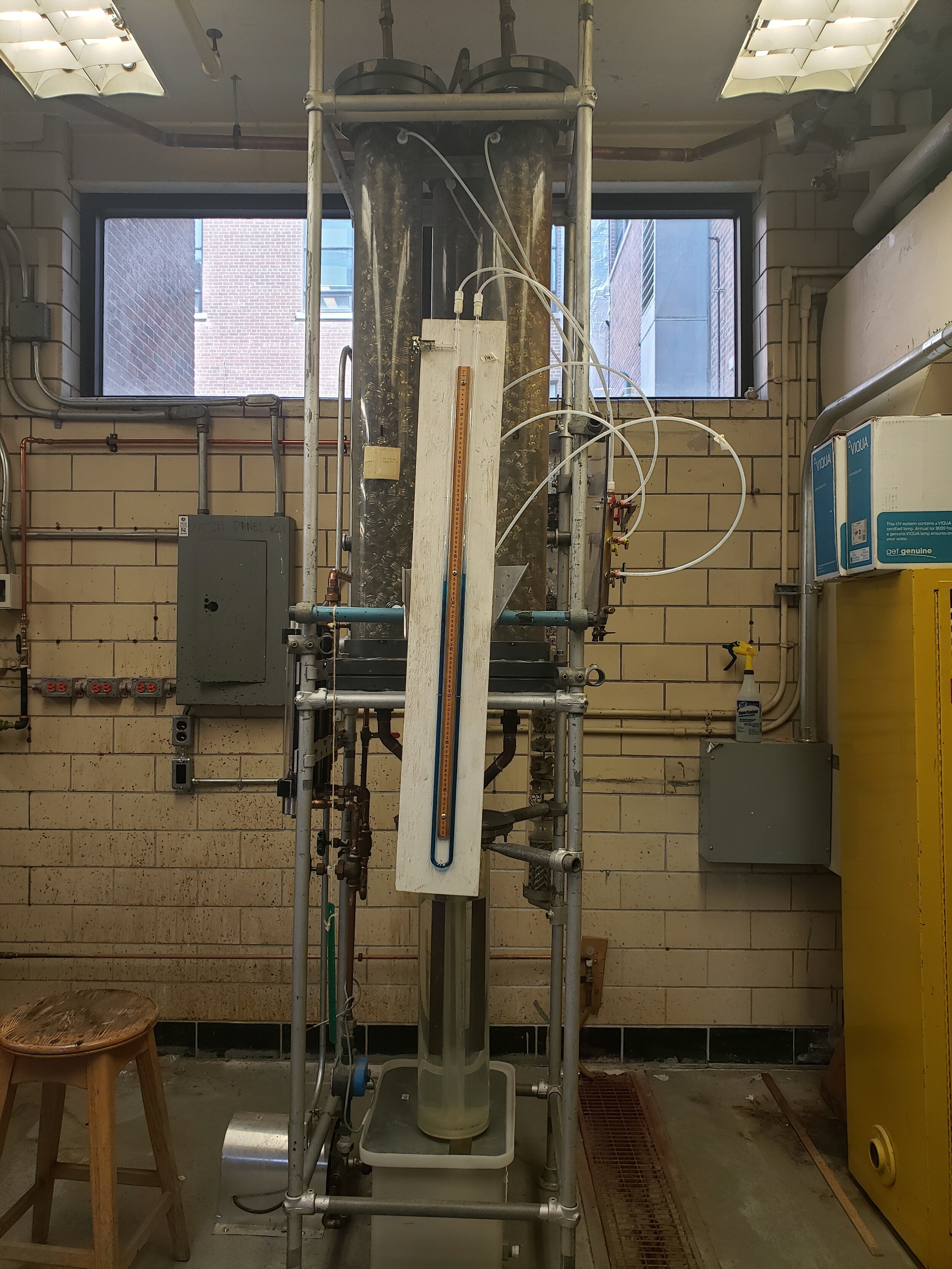

Drag Force Testing Columns

With any flowing system, friction will exist. It is not uncommon to want to separate slurries or have solids existing in a liquid system. Sedimentation processes rely on these concepts so that we can separate the finer and finer particles out of the liquid phase and collect it.

In this lab, you will be exploring the friction (drag) an object experiences when there is a relative flow between the solid object and the fluid.

Flow Through Pipes and Fittings

Compared to the drag, we are still exploring the frictional forces experienced in flowing systems. However, here we are instead exploring the friction (head loss) a fluid will experience when flowing through valves, flow meters, bends, etc. Here, we are more concerned with looking at how the pressure drop fluid experiences when passing through fittings so that we can use this information to design a pump to overcome the head losses.

The use of distillation columns can be found in most plants in industry. We consistently use distillation columns for separation and purification processes. One type of distillation column commonly used is a packed distillation process.

Engineers can use different types of packing materials to meet their different design specifications. Packings of different sizes and shapes can be oriented randomly or in a structured manner.

The type of packing geometry and materials affect the hydrodynamics present in the distillation tower. In this section, we will be discussing how flooding can occur, why it occurs and how we use packing analysis to predict when a tower might flood.

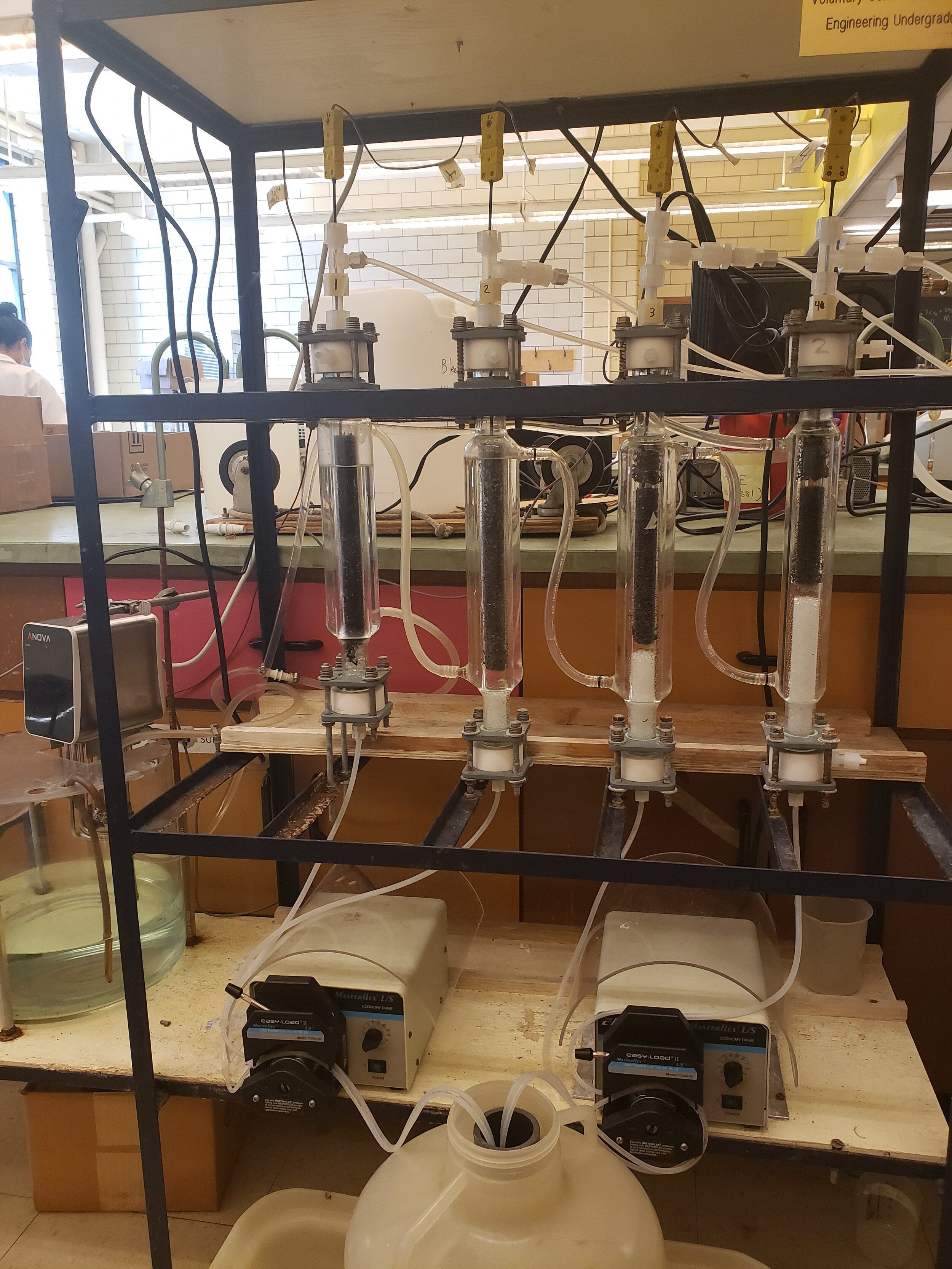

In this section, we will be discussing the design of a PFR with a packed bed of catalysts (Packed bed reactor or PBR for short). In our discussion, we will be analyzing a bleach degradation system and use this experiment to analyse different, important parameters in our system.

This lab will give you first-hand experience in simulating an industrial-scale process under lab conditions, frequently done by engineers, so that they can upscale the process safely and efficiently.